Anodic oxidation

Anodic oxidation (anodizing) is a form of surface treatment of aluminum and its alloys, where the natural propensity of aluminum is being used for oxidation.

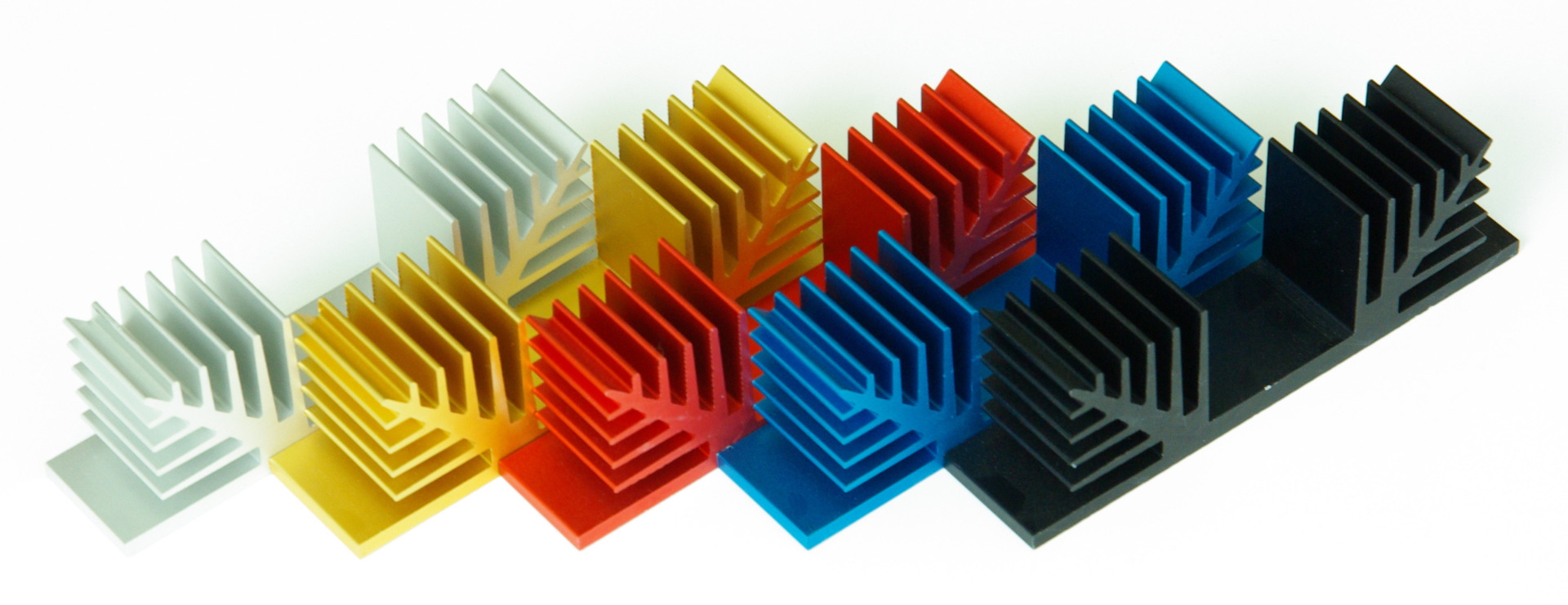

During the anodizing there comes to an oxidation on the surface of the material and a layer of aluminium oxide is being created. The micropore structure of the layer is being coloured and filled in chemical sollution and the resulting material is smooth, hard and chemical, corosion and abrasion resistant.

The advantages of surface treatment:

- Resistance to corrosion,

- Abrasive resistence,

- Increased surface hardness,

- Decorative effect.

Anodizing services

Anodic oxidation (anodizing)

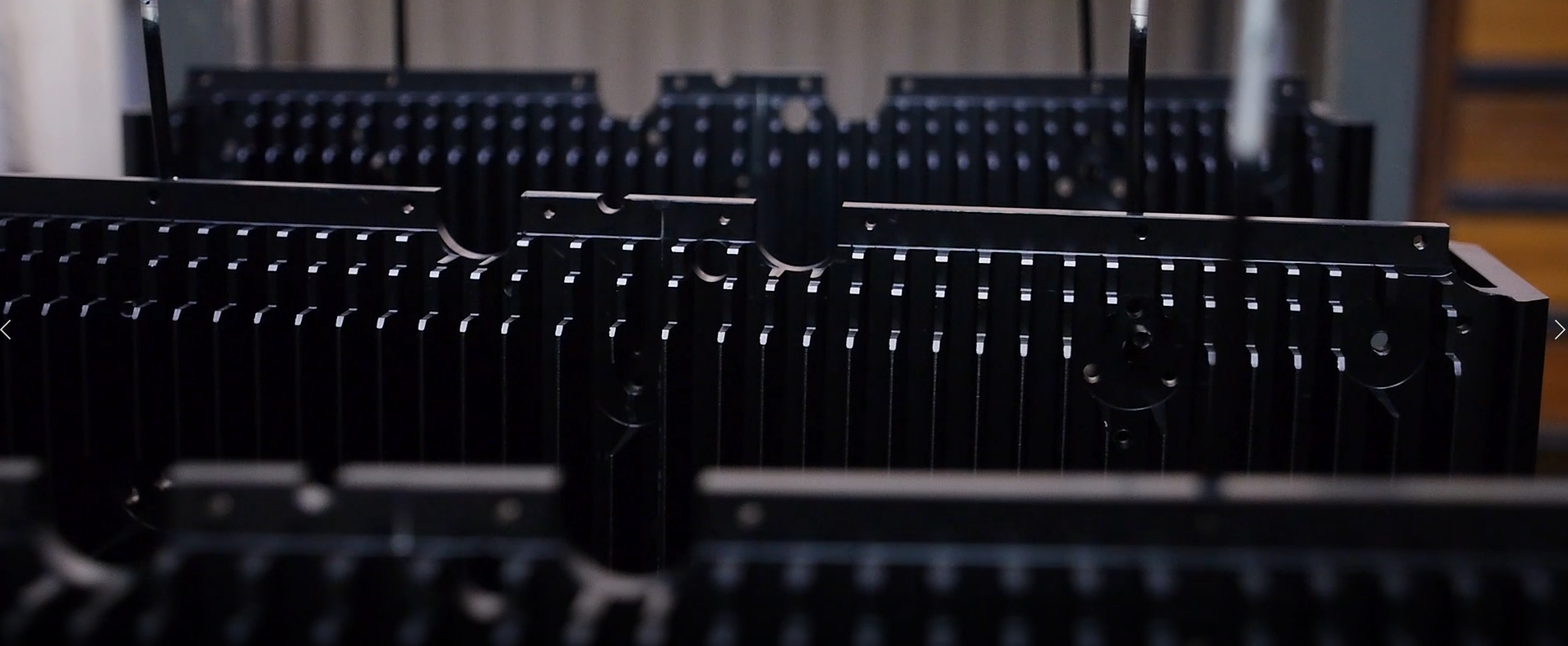

By anodizing we create a lazer of aluminium oxide for decorative or functional surfaces with the thickness of 10 to 15 μm. We offer black and natural anodizing, but we are open to produce other colour shades after consulting with the customer. The advantage of the anodized material is the unconductivity of the surface as well as the decorative effect.

Titan coating is a technology, when a titan layer is being created on the surface of the material, which prevents the aluminium oxidation. Using this technology of the surface treatment we can ensure the anticorrosive protection of the material and the surface remains electrical conductive.